The Knitting Option

Project Type : Student Work - 2019

The Knitting option is a process led project focused on experimenting with 3D knitting.

Fascinated by the evolution of an ancient hands-on process transformed into an automated and digitized additive manufacturing technique; I searched for opportunities from an industrial design point of view.

The goal of this project was to combine multiple manufacturing processes and fabrication techniques to promote emerging technology. Our role as designers is to find purpose to the techniques provided by the industry in order to develop innovative products while applying sustainable production models in terms of material waste, cost, labor, and efficient use of resources available locally. By producing the knits locally and on demand, we are reducing waste, excess stock, and consequently connecting the designers with the manufacturing.

How might we interfere in placing digital knitting as part of the open source movement?

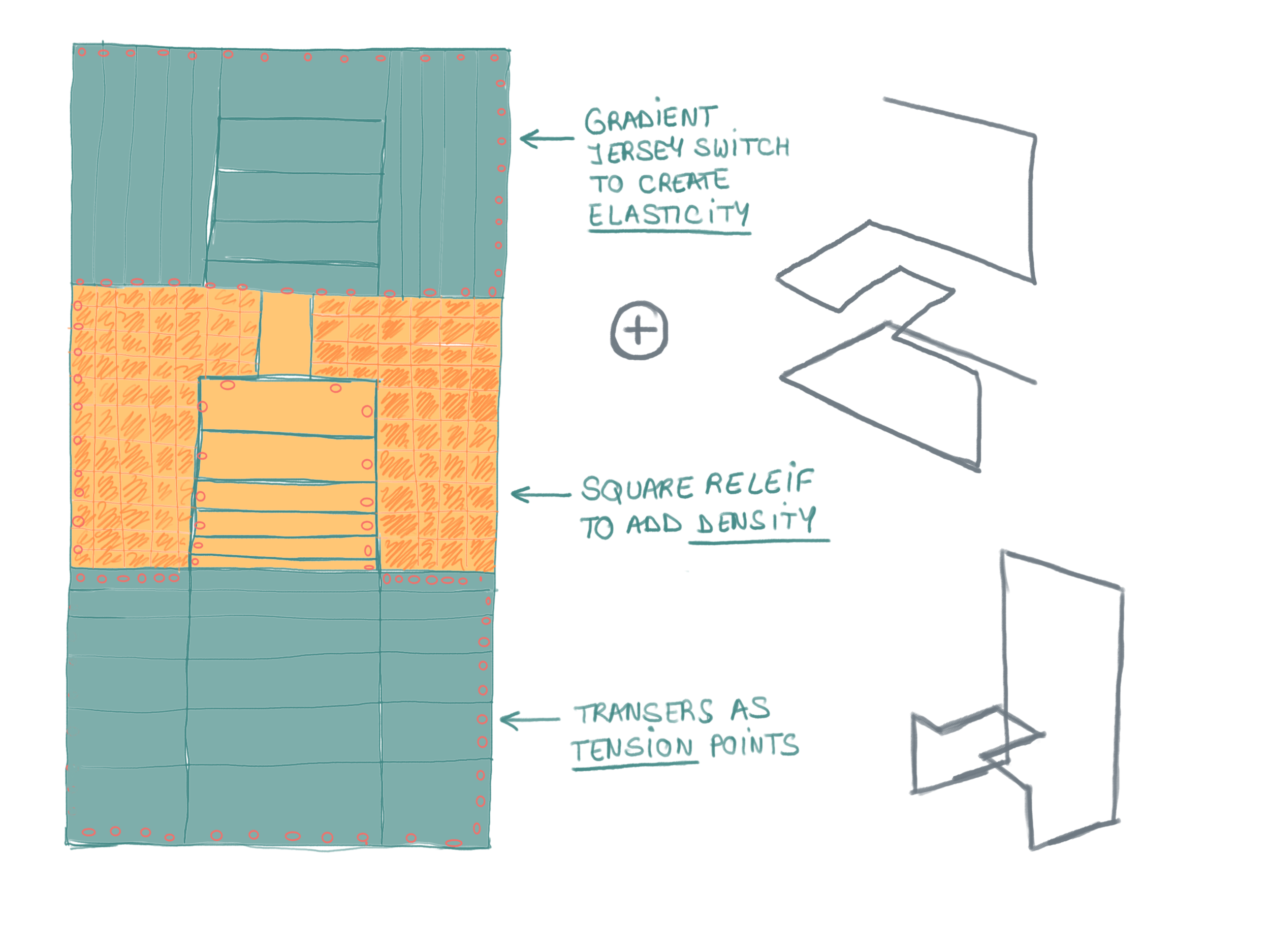

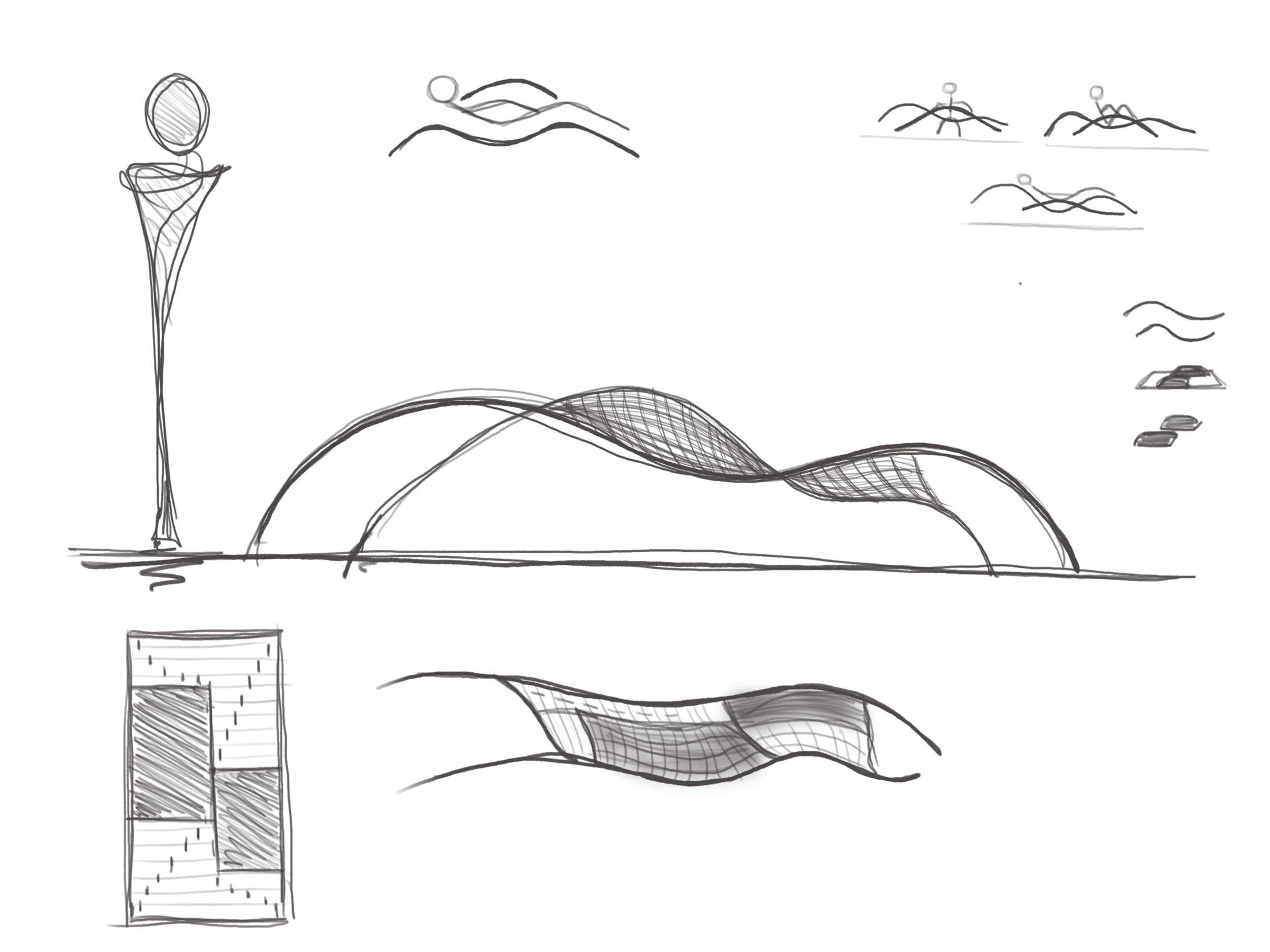

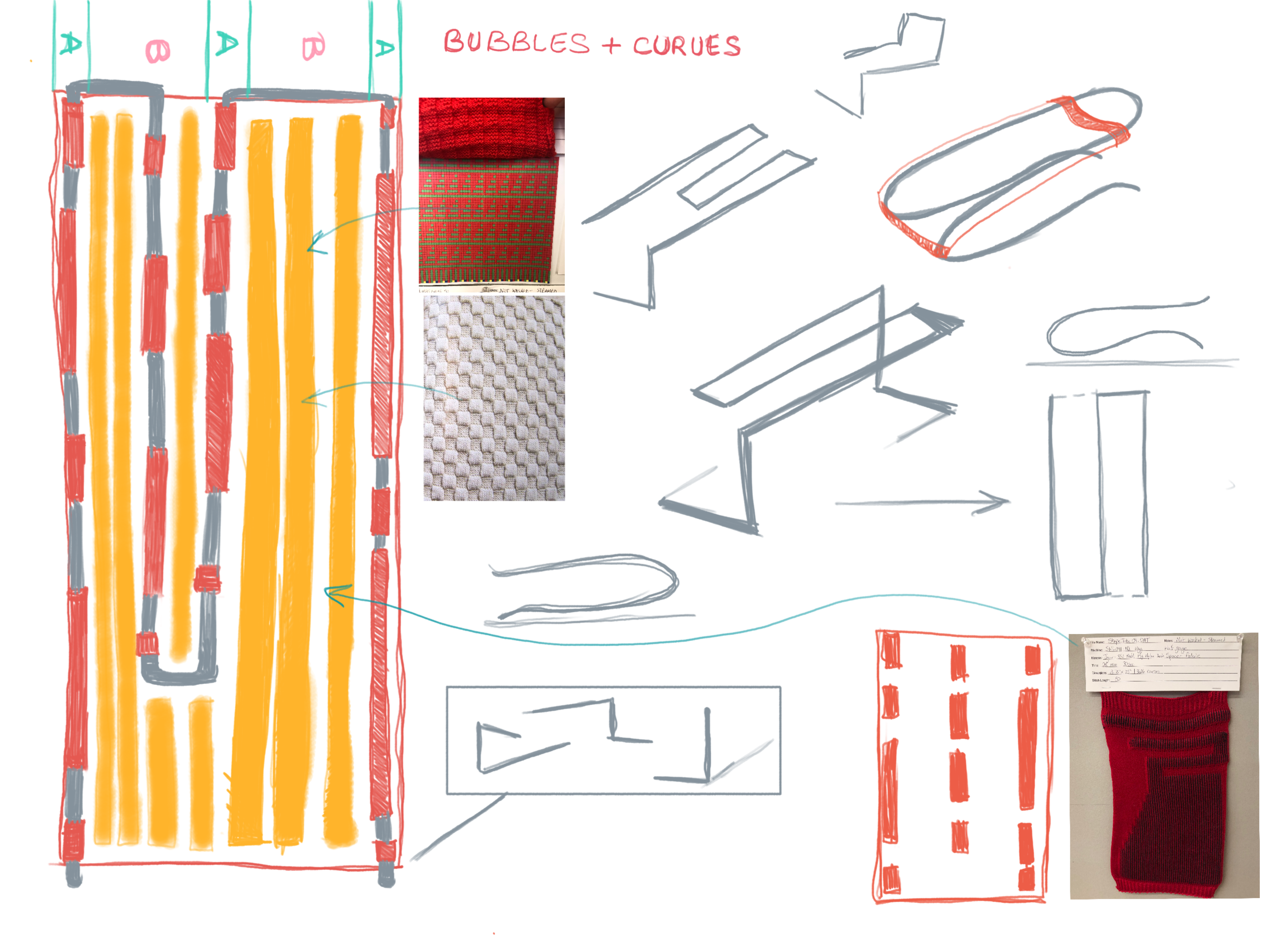

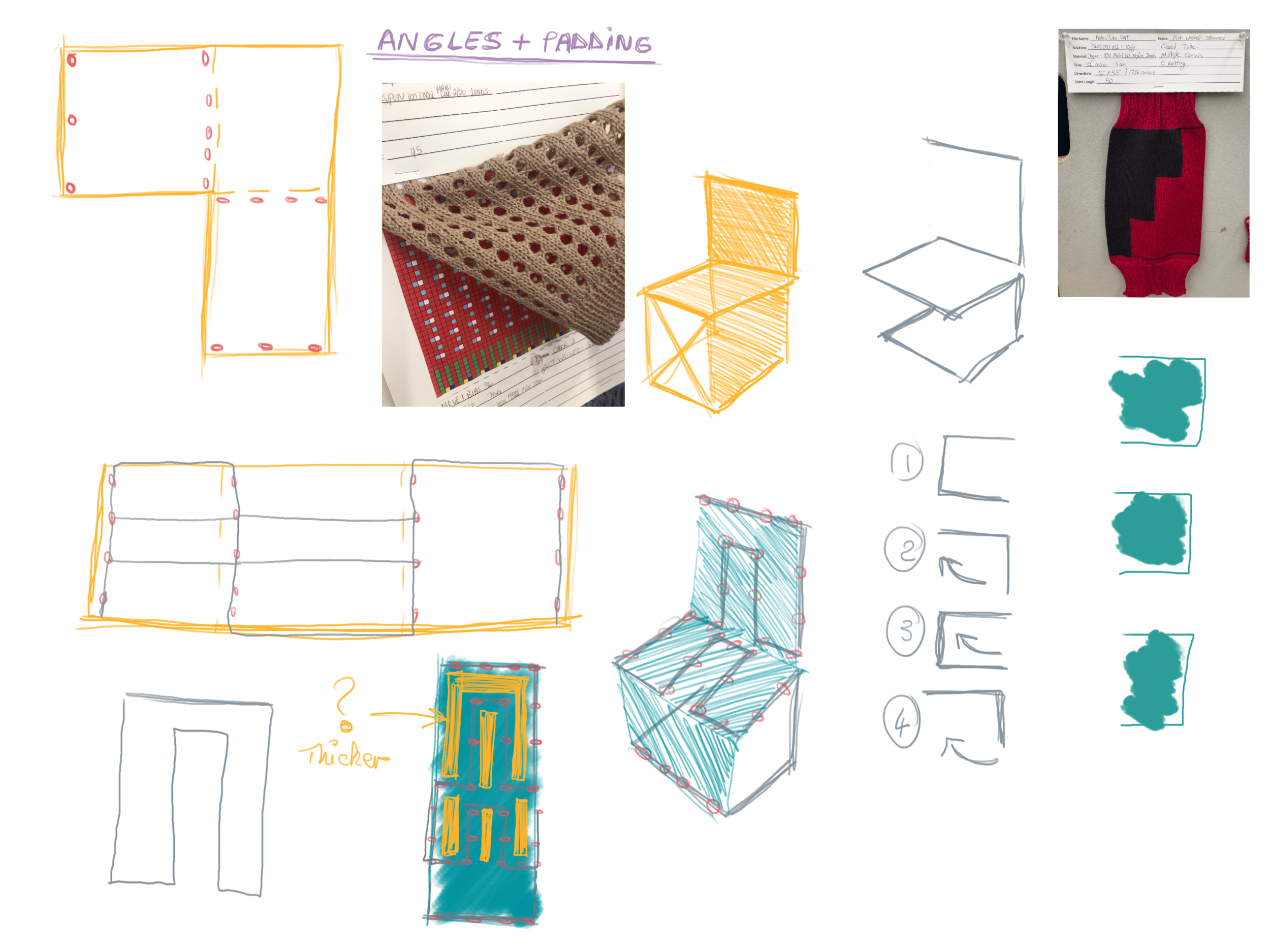

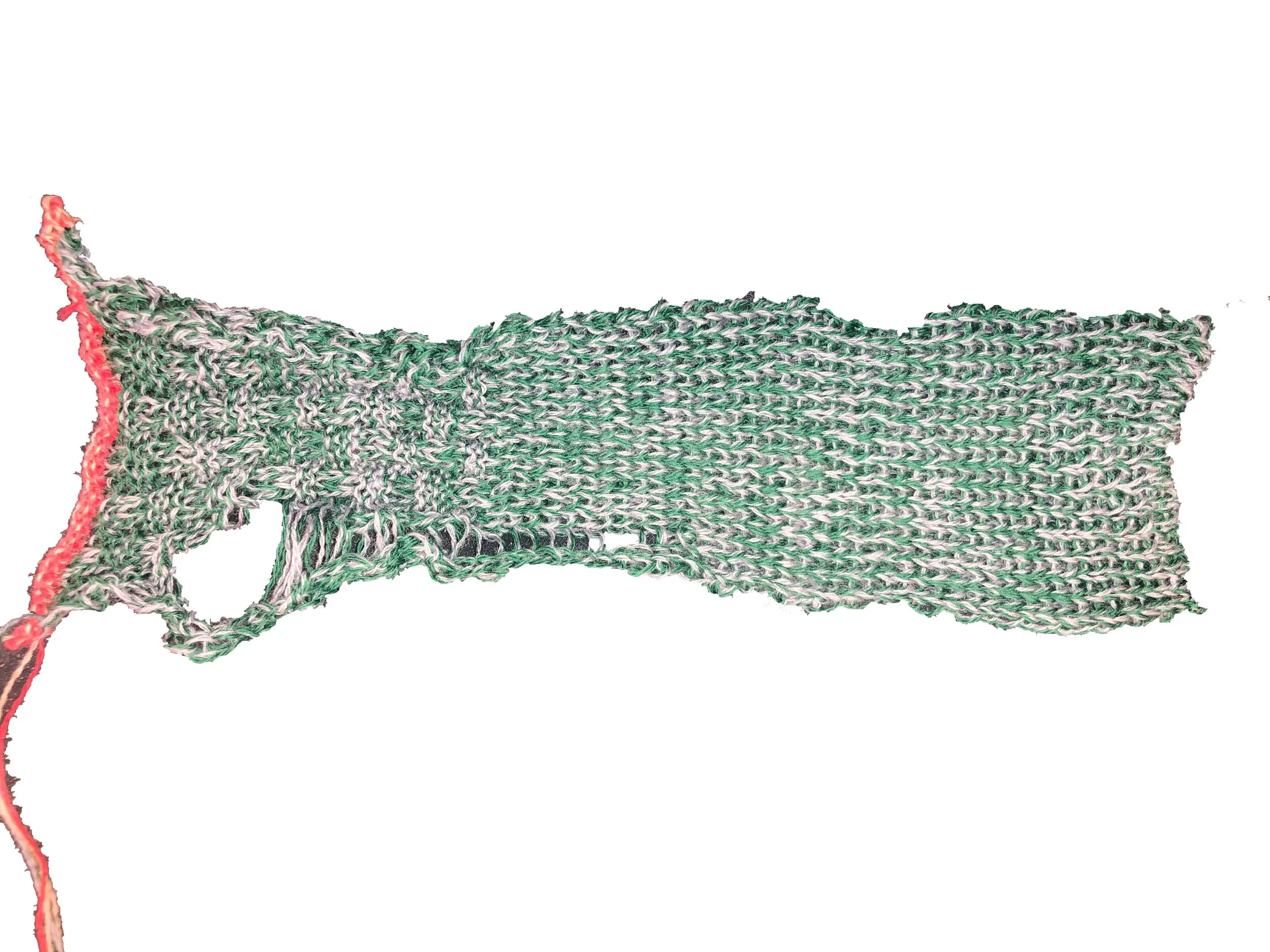

I first tackled this project by understanding knitting basics then moved on to learning the Apex Program associated to the Shima Seki knitting machine. The challenge was shifting from visualizing in 3D, to yarn, to 2D, to volume again which led me to establish my own process of merging ideation methods.

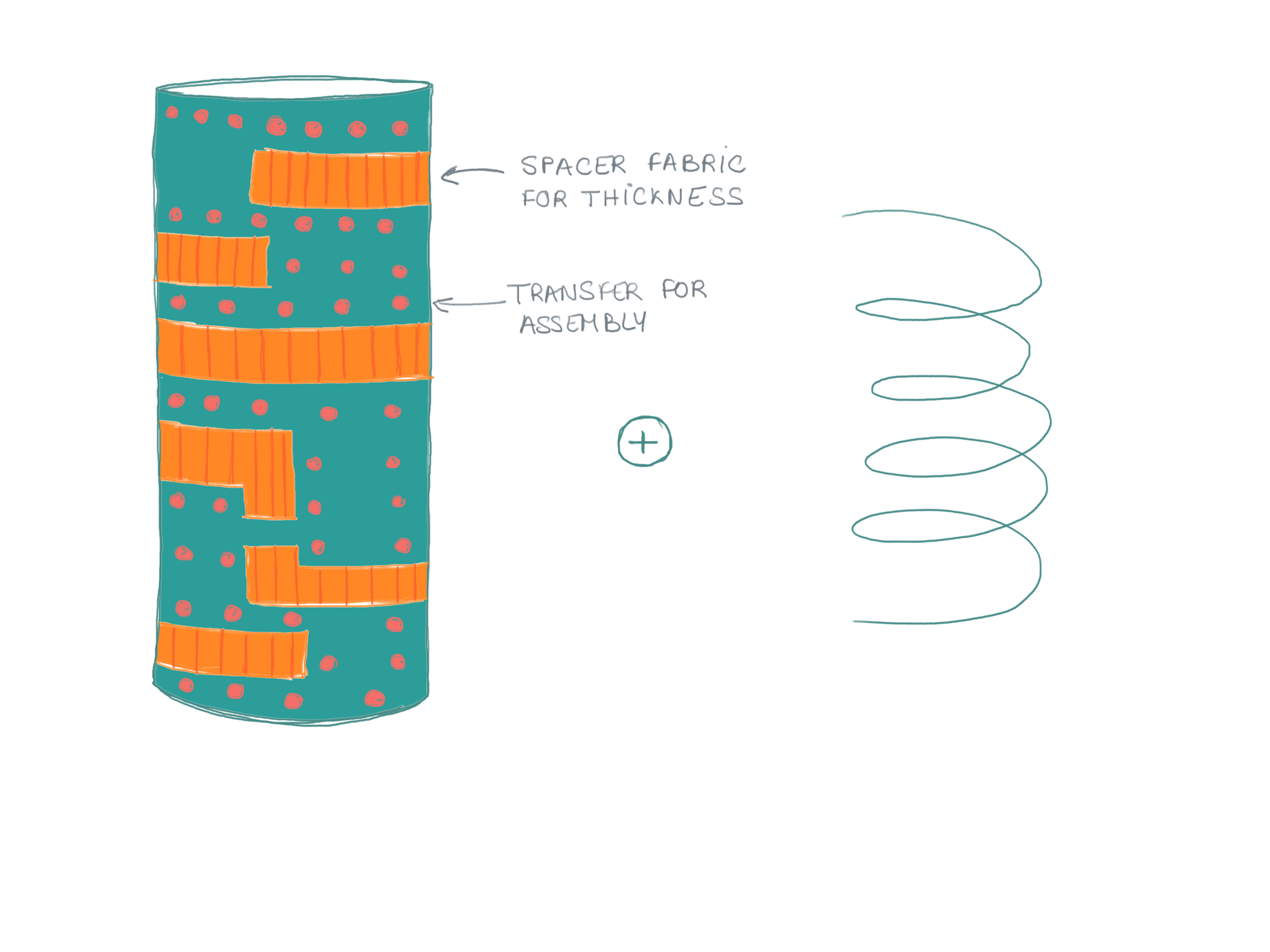

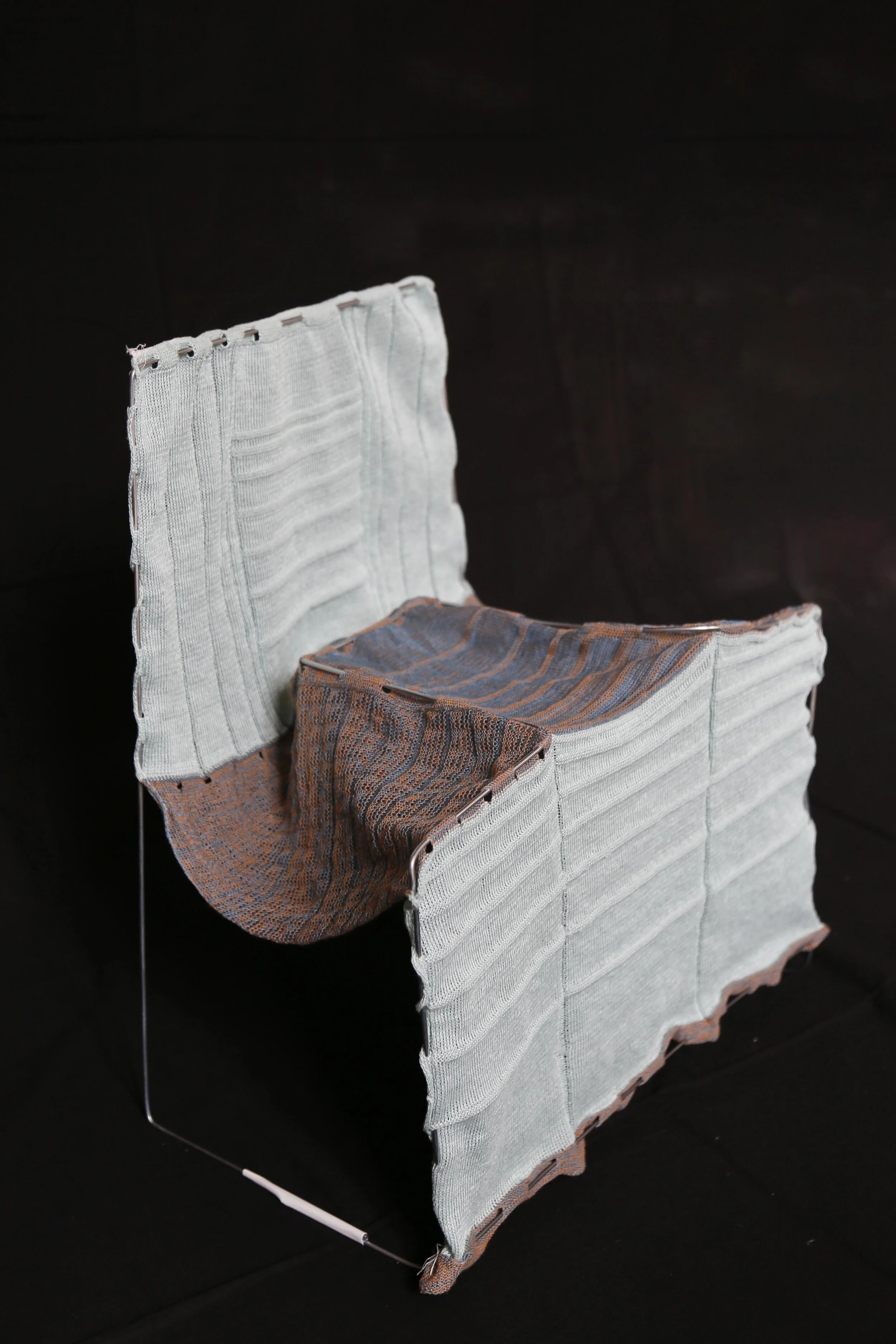

Once I grasped enough of the phases of fabrication, I introduced stainless steel tubular structures to the knits using the DiWire Pensa to explore shapes and possible typologies for my product. The contrast between the flexible yarn and solid metal wires lead me to further explorations within the industrial design scope.

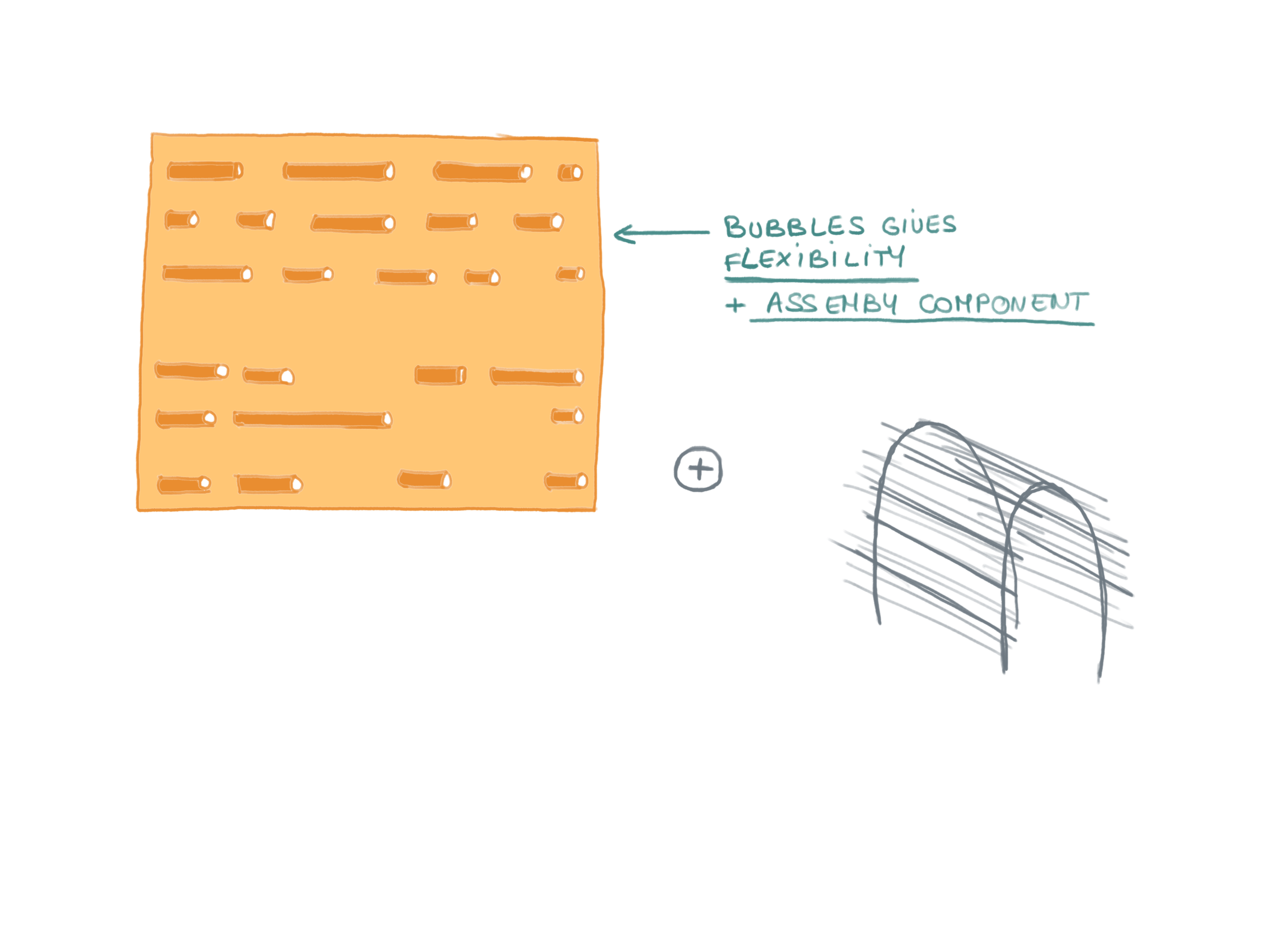

Visualizing the result as a volumetric fabric, I focused on translating knits details, commonly used for decorative purposes, as assembly components- attributing function beyond aesthetic.